MAX1 technology enters the Chinese iron & steel market

May 21, 2020

MAN Energy Solutions has been awarded the order for the first AG-MAX1 compression unit for a blast furnace application in the People’s Republic of China.

Shandong Province Metallurgical Engineering Co. Ltd. (SDM), an international engineering technology company and EPC with a strong foothold in Chinese iron & steel industry, has placed an order with MAN Energy Solutions for the MAX1 axial compressor technology.

The end customer Shandong Iron & Steel Group Laiwu Co. Ltd., will take the air compression unit into operation at their steel works in the Chinese city of Jinan, Laiwu district. It will be used as blast furnace blower with a pressure ratio of approx. 6 to supply the blast furnace with air and thereafter to provide the oxygen for coke combustion.

“After a total of 18 successful projects for the Chinese air separation sector, we are proud to provide our innovative axial compressor solution to the iron & steel industry of China,” says Dr. Marco Ernst, Head of Region Asia Pacific Turbomachinery at MAN Energy Solutions in Shanghai. “Not only will our customer benefit from the many advantages our MAX1 technology has to offer, but also from MAN’s long-term expertise in this field.”

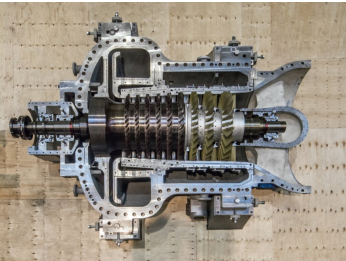

MAN Energy Solutions has a long experience in delivering axial compressor trains for manifold applications, such as the worldwide largest axial FCC main air blower with a capacity of 750,000 m3/h. MAX1 represents the third generation of MAN’s axial compressor technology. It has already proved a commercial success with seven blast furnace compression units deployed in four different iron and steel plants around the globe.

The axial compressors and the related blading technology convinced the customers through the enhanced power density and performance, while meeting expectations in terms of reliability. Technology wise, this was achieved by MAN’s long-term experience with more than 1000 axial casings since 1933 and combining the advantages of compression technologies based on high power density with the ones of industrial large-volume compressors, which have a large operating range. The result is a lower power consumption together with an improved surge robustness along the whole operating range. Moreover, the new rotor dynamics had a significant effect on the overall casing design: the reduced rotor mass, the smaller bearing size as well as the utilization of fewer blades and vanes automatically led to a compact design with reduced weight.

“Axial compressors are at the heart of processes in the industry sector and as such exert a crucial influence on profitability. Our MAX1 technology addresses exactly this topic with its significantly reduced power consumption, meaning both lower operating costs and environmental benefits in terms of less CO2 emissions,” explains Thoralf Schaefer, Head of Sales Basic Industries at MAN Energy Solutions in Oberhausen, Germany.

The order for SDM consists of a completely assembled axial compressor MAX1 type AG100/11M, including gearbox with the rotor turning device as well as auxiliary equipment.

A great part of the manufacturing process will take place in MAN’s Chinese production site of Changzhou. Delivery and installation of the AG-MAX1 compression system is scheduled for the first quarter of 2021.